Stone Slabs

Humans have used natural stone to prepare, present and consume food for ever. Bowls and flat slabs form relatively quickly by grinding grains with or against other rocks. You can still find some Native American communal food preparation areas in wilderness areas around the US. Grinding areas abound in Yosemite National Park. Favorite locations are on enormous stone areas close to streams. Flat rock and round cylindrical tools were best for fine flour. Because stone is abundant, long lasting and easy to clean, Yosemite granite was a great food preparation material.

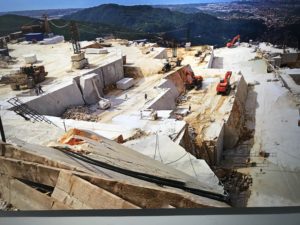

Because of its abundance and durability, stone has been quarried, used and worked by humans for thousands of years and on every continent. Natural stone counter materials are created by quarrying large stone blocks and slicing them into 2-3cm thick slabs. For today’s homeowner, stone slab options available now include marble, quartzite, granite, slate and engineered stone like Caesarstone or Silestone.

These slabs can create one-piece countertops as large as 6’x10’ and even larger by joining “book-matched” slabs with precision joinery. By precision joinery, I am referring to computer aided cutting machinery that can essentially finely cut and shape stone like butter. Hard butter that is. Once in place, a stone countertop is an installation with very long life. To reduce maintenance, sealers are recommended for most natural stone countertops in order to prevent stains from getting into the pores of the material. A glass top can also be used on very porous stone like marble to help protect it from damage.

To-Do

- If you have stone countertops, determine what kind of stone material it is made from.

.hommaint

- 1x per year: Clean, hone and seal marble countertop materials and inspect and re-caulk around joints, sinks and other dissimilar materials.

- Every 2 years: Clean and seal granite and quartzite counter top materials and inspect and re-caulk around joints, sinks and other dissimilar materials.

Know stone characteristics when choosing

Marble:

Marble is gorgeous and silky in appearance and its attractiveness makes it highly sought after for luxury living. Unfortunately, marble is also softer and more porous than other stone materials making it easy to damage and will absorb staining liquids. Its composition is calcium rich and etching by acidic foods like citrus fruits, tomatoes and juices is also a problem. Marble sealing prevents stains but is expensive and short lived. As a result frequent reapplications are needed. Because of these characteristics, marble is a good choice for bathrooms, showers and tabletops that are not subject to cutting and cooking.

Granite:

This is a grainy appearing igneous rock formed by the slow crystallization of magma within the earth’s crust. It is hard and massive with few cracks.

In the commercial world of countertops and stone features, a granite is a rock with visible grains that is harder than marble. Gabbro, basalt, pegmatite, schist, gneiss, monzonite, anorthosite and diorite are all considered “granites”.

Granite is hard, scratch resistant, polishes to a high gloss and is not affected by food acids. Most granites are non-porous and yet all can benefit from a sealer to prevent stubborn stains that might occur during the cooking process. Granites come in an unending array of natural colors and patterns making every installation unique and one of a kind.

Quartzite:

Quartzite is an extremely hard, metamorphic rock that was once pure quartz sediment. Tectonic forces deep in the earth squeezed and heated these sands. The resulting quartzite material has a sandy, fine grained appearance with glassy or shiny areas embedded in the structure.

Many quarry’s have found attractive versions of this material with striking colors and veins that produce unique and gorgeous patterns ideal for architectural applications. In fact, our kitchen counter has pattern that we have nicknamed “the duck”. Resistance to abrasion, low porosity and acid resistance make this material highly suitable for kitchen use. Quartzite surfaces also accept “honing” or “leathering” treatments that add a soft and unique feel to their surfaces. Treat these countertops with sealant as you would granite.

Engineered stone:

The design industry knows this material as “Quartz”. Crushed quartz material is the main ingredient of Quartz. Using a strong resin binds the pieces together to make large slabs of artificial stone. The resulting material is hard and durable with an extremely uniform appearance. It’s resistance to heat and UV light can be variable depending on the resin used. Check with the manufacturer for warranties on heat resistance and the effects of UV light over time. Quartz tops are durable, scratch resistant and not subject to normal kitchen stains. Quartz slabs can be made in a stunning variety of colors and patterns.