Preserving and protecting exposed wood beams

Large wood timbers and beams are widely used in architecture because they are strong and impressive looking. They are also popular because they are easy to work into shapes that can be used both structurally and aesthetically. Wood beams are used to make headers, columns, exposed roof elements, trusses and rafters. Exterior uses include patios, trellises, arbors, rafter tails, ridge extensions and many others. Massive solid wood beams make beautiful architectural statements.

For maximum strength, wood timbers must be cut “free of heart.” In other words, to avoid splitting, they must be cut outside of the center of the log. Their sheer size requires that wood beams of this sort be milled from large trees. These larger trees are the oldest and rarest trees in the forest and produce some of the most valuable and desirable lumber. All this makes solid wood beams expensive compared to normal dimensional lumber.

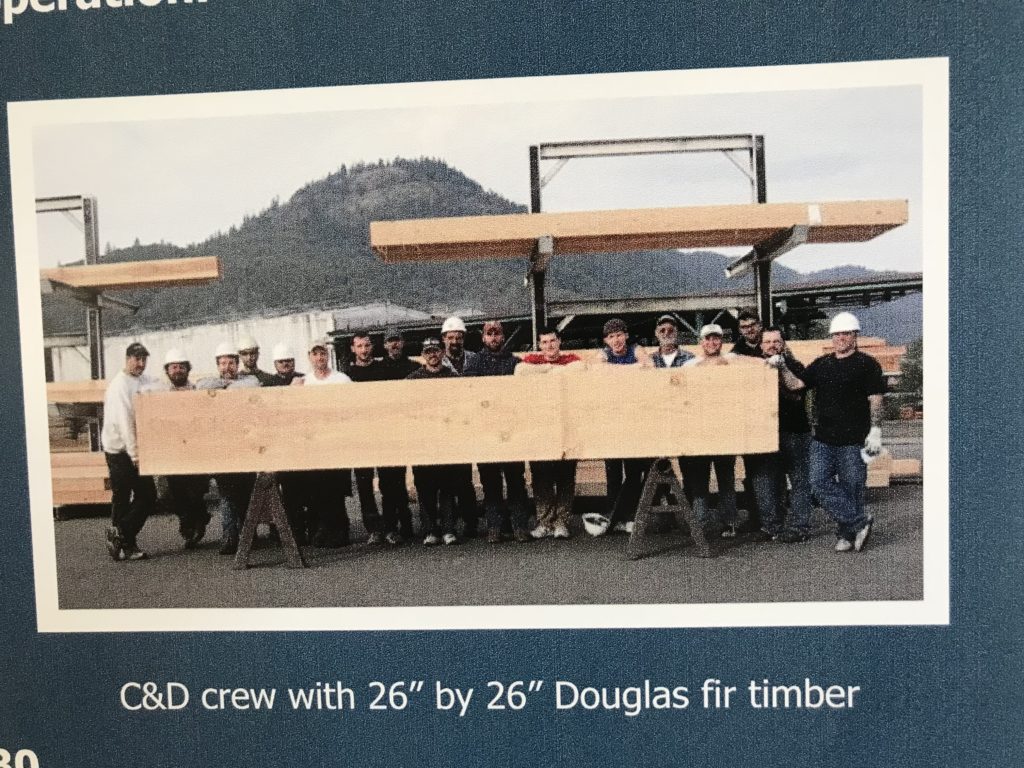

Big timbers require special trees…and mills

In Oregon there are only four remaining mills that specialize in producing truly giant beams. Starfire and CD Lumber are two of the best and only cutting mills left. Starfire advertises that they can produce timbers up to 36”x36”x 28 feet long. This is a truly immense piece of wood. Here is a photo of a 26”x26”x24’ long beam for comparison.

When an order comes in for a really big timber, they will put out requests to quality suppliers like Basco Logging Inc. to locate and secure the giant older growth logs needed. These logs must not only be large, they must have dense grain (closely spaced rings) for strength. The four specialty “cutting” mills are the only left that have the huge equipment necessary to saw these giant logs into massive beams, then carefully kiln dry them so they are ready to ship.

Protecting exposed big timbers

To extend their useful lives and preserve that premium value, big beams exposed to the weather need special help. After large dimension lumber is cut at the mill, it slowly begins to lose moisture. The moisture loss is fastest at the outside surfaces and is slower on the interior of the wood. These differing drying rates mean cracks will appear. For interior beams this is not a problem. But for exterior applications, cracks allow moisture and insects to get into the heart of the wood and cause damage. If your home has large wood beams that are exposed to the weather here are some steps you can take to preserve them.

Good design

The first thing is good design. If you are erecting beams outside design the structure to quickly shed water. Avoid complex joinery that might absorb or trap water. Also avoid providing spaces for insect attacks or bird nesting. If you are using large timbers or logs for columns, be sure the base is treated with preservative and separated from the foundation with metal flashing. Foundations for wood columns should extend up high enough to prevent any contact with soil or standing water.

Coatings and preservatives

p>The next thing to do is to treat the raw beams with several coats of a penetrating sealer and stain. Apply these coats by brushing them on heavily and allowing the stain to soak in. Exposed to elements these protective coats may only last a year or two. Don’t go by warranties or manufacturers claims when deciding if a new coating is needed. Be ready to reapply as soon as the beams appear dry and faded. Get Penofin stain and sealer at Amazon. Learn more about paint and coatings here.

Protect the tops

The very tops of exposed beams are especially vulnerable. The flat top surfaces can allow water to pool and will also become an attractive landing spot for birds and insects. Inevitable cracks and splits on the top surface will allow water to penetrate deep into the wood causing havoc. Since the beam tops are out of sight, it’s easy to miss the fact that any protective coatings have disappeared. Unprotected beam tops are vulnerable to dry rot that can quickly develop. Once any rot starts, it can quickly spread deep into the beam and ruin it. To protect smaller joists you can use these prefabricated Imus caps.

Here is large timber only a year and a half after the application of four coats of stain and preservative.

To prevent these horrors, beam tops should be covered by a sheet metal cap designed to shed water off the top surface. Copper is nice as it is easy to form and ages to a nice dark patina color that goes with just about anything. Galvanized steel sheet metal can be used also but may need to be painted to match your needs. These metal shields do a great job of protecting the top surface from any ill effects caused by rain, sun, snow, birds or insects.

Summary

Preserving exposed wood timbers and beams is important because they can only be made from huge ancient trees. Many may be over 500 years old. These big chunks of wood may look indestructible but without protection weather, insects and time will destroy them. Good design, regular treatment with preservatives and stains and the installation of metal caps to the exposed top surfaces can make them last a long time.