Garage Doors and Openers

Garages and garage doors have an interesting history. Starting out as carriage houses first, these structures were usually located only a short distance away from the main home. This was in order to remain conveniently close to the horse who was in charge of pulling the carriage around.

When the automobile became popular these carriage houses were converted for use with cars. With a car, folks soon gave up the horse and with horses gone, so were the problems associated with feed, flies etc. Now the enclosure could be conveniently attached to the house and the modern garage was born.

An overhead version of the garage operator came into being in 1921 and by 1926 could even be fitted with an electric motor. This made car ownership fantastically cool, but we had to wait another 40 years to get a reliable, secure remote control. One that would not open the neighbor’s garage at the same time as our own.

Mechanical description

Sectional garage doors consist of a bunch of narrow horizontal panels held together with bolts and hinges. The bolts in the entire assembly vibrate when in use and need regular tightening. The tracks for the door rollers should be clean and free of debris and the bearings of the rollers should be lightly lubricated annually. Garage overhead doors are not air tight. Severe weather conditions may result in some rain or debris being blown in around the door.

Overhead garage doors are big and heavy, some weigh as much as 400 pounds or more. In order to lift them, garage doors are fitted with powerful counterbalance springs that do most of the heavy work. You can see these big springs along the top of the garage opening on the inside when the doors are in the down position. These springs are rated to last at least 10,000-15,000 cycles. As durable as they are, sometimes one will break and that can be dangerous.

Garage door and opener safety

To avoid being trapped, the UBC requires garage openers to have a quick-release mechanism. This is a red handle on a cord that allows the opener to be disconnected in the event of a power failure or spring break. Garage openers are also required to have safety sensors. As a result they can detect objects in the path of the door and reverse if it strikes a solid object.

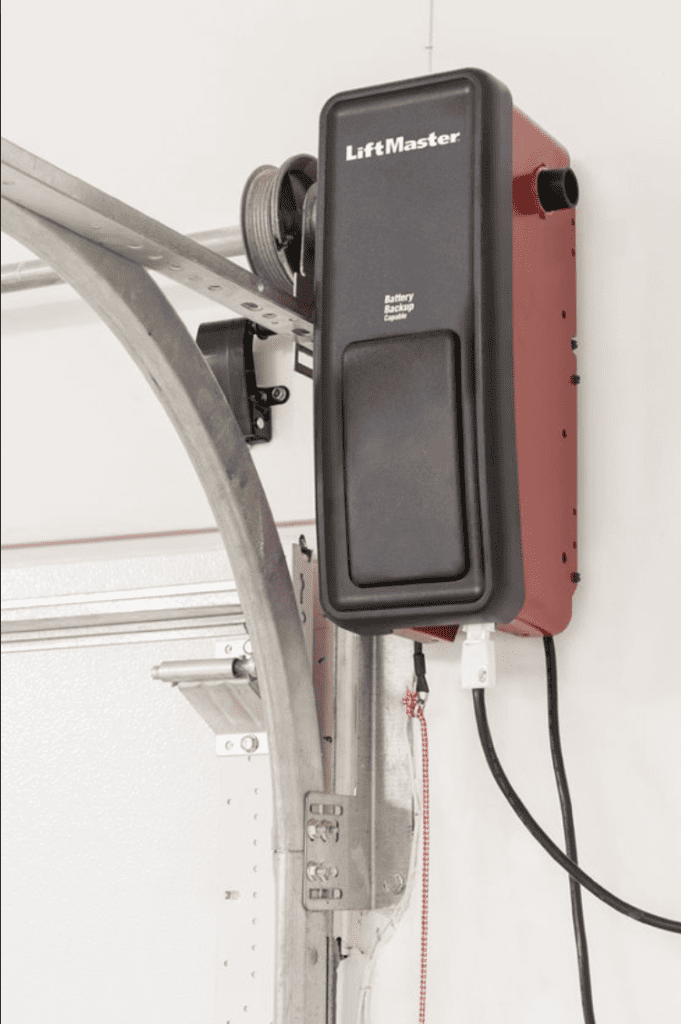

There are optional types of mechanisms for the openers. I prefer the “jack shaft” type opener where the motor is mounted on the wall next to the door springs. Because I don’t like having the motor hanging over my car. You can order one from Amazon here.

To-Do

- Read the manual to be familiar with the steps for manual operation of the door in the event of a power failure. Follow the manufacturer’s instructions for safe and reliable operation.

- Do not allow anyone or pets near the door and keep hands and fingers away from all parts when in motion.

- Do not allow children to play with or around the door. If the large seal at the bottom of the door fails is should be replaced.

- If debris continually blows into the garage from around the closed garage door, inspect all of the weatherstripping and repair as needed.

Maintenance

- 2x per year: inspect and tighten all the bolts and nuts holding the door and opener together.

- 1x per year: Lubricate the roller bearings and other moving parts. Do not get lubricant in the track itself in order to avoid “skating” of the rollers in the track.

- 1x per year: Replace the convenience bulb once a year to avoid finding out the hard way that it is not working.

- 1x per year: Most garage doors have a key lock that nobody ever uses. If this lock becomes stiff, apply a silicone or graphite lubricant. To prevent damage to the garage door opener, be sure the door is completely unlocked before using the operator.